Product Description

Product Description

Product introduction

| Gear parameter table | |

| name | numerical value |

| normal module | 8 |

| number of teeth | 33 |

| profile angle | 20 |

| helix angle | 10 ° |

| accuracy class | 6 |

| material quality | 18CrNiMo7-6 |

| heat treatment method | carburizing and quenching |

| surface hardness | HRC58-62 |

| Core hardness | HRC35-45 |

My advantages:

1. High quality materials, professional production, high-precision equipment. Customized design and processing;

2. Strong and durable, strong strength, large torque and good comprehensive mechanical properties;

3. High rotation efficiency, stable and smooth transmission, long service life, noise reduction and shock absorption;

4. Focus on gear processing for 20 years.

5. Carburizing and quenching of tooth surface, strong wear resistance, reliable operation and high bearing capacity;

6. The tooth surface can be ground, and the precision is higher after grinding.

DESCRIPTION

The maximum machining diameter of our company’s cylindrical gears is 1250mm, and the machining modulus ranges from 0.5 to 20. The highest accuracy level of gears can reach international GB11365-89 4. The commonly used materials are 18CrNiMo7-6/20Cr2Ni4A/20CrNi2MoA/20CrMnTi/20CrMnMo/42CrMo, etc. The commonly used heat treatment processes are carburizing, quenching, nitriding, and quenching and tempering. Widely used in various fields such as aerospace, rail transit, mining and metallurgy, engineering vehicles, port machinery and ships, industrial gearboxes, industrial automation, etc.

HangZhou Ke’an Transmission Machinery Co., Ltd. is a professional manufacturer of high-precision gear transmission parts. The company is located in HangZhou City, HangZhou, a land of fish and rice in the south of the Yangtze River. It is adjacent to the Xiake Exit of the HangZhouang Expressway for 6 kilometers, the HangZhou South Exit of the Xihu (West Lake) Dis. (ZheJiang ZheJiang ) Expressway for 6 kilometers, and the HangZhou Station of the South HangZhouang High speed Railway for 6 kilometers. The location is superior and the transportation is very convenient. The company has an annual production capacity of more than 35000 high-precision gear transmission parts.

The company has 6 American Gleason CHINAMFG 275G/800G CNC spiral bevel gear grinding machines, German Kappa VX55/59 CNC gear grinding center, Swiss Mager KS-42 high-precision straight bevel gear grinding machine, Swiss Stuart high-precision CNC internal and external cylindrical grinding machine, German ZEISS coordinate measuring instrument and a set of American Gleason 1500GMM gear measuring center, which can collect and detect the profile of the tooth. It has a complete set of heat treatment production line of EPSON controlled atmosphere multi-purpose furnace, with more than 200 hosts and supporting equipment. The product has complete detection means, and is equipped with precision detection instruments such as material physical and chemical analysis, mechanical property test, ultrasonic flaw detection, magnetic particle flaw detection, etc. The gear processing modulus ranges from 0.5 to 20, and the highest accuracy level can reach international GB11365-89 level 4. The products are widely used in aerospace, rail transit, mining and metallurgy, engineering vehicles, port machinery and ships, industrial gear boxes, industrial automation and other different fields.

With professional manufacturing experience and strong design and development ability, the company can conduct mapping or design various non-standard special high-precision gear parts according to the technical parameters provided by users. Tight GB/T19001-2016/ISO9001:2015/AS9100D-2016 quality management system certification, perfect ERP process management and MES information management ensure the controllability of product quality management. The company has passed the CCS classification society factory certification of China Classification Society, and is praised by the industry for its excellent products, reasonable prices, short production cycle, timely service and other advantages.

The company adheres to the corporate spirit of “diligence and pragmatism, exploration and innovation”, and the business philosophy of “professional casting quality, integrity winning the world”. It shoulders the mission of having strong gears and strong equipment, and strives to make greater contributions to the world’s transmission.

FAQ

| Main Markets? | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, Asia |

| How to order? | * You send us drawing or sample |

| * We carry through project assessment | |

| * We give you our design for your confirmation | |

| * We make the sample and send it to you after you confirmed our design | |

| * You confirm the sample then place an order and pay us 30% deposit | |

| * We start producing | |

| * When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| * Trade is done, thank you!! |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Cast Steel |

| Customization: |

Available

| Customized Request |

|---|

Can sun gears be used in automotive applications?

Sun gears are widely used in various automotive applications, playing crucial roles in different systems. Let’s explore the automotive applications where sun gears are commonly employed:

- Automatic Transmissions:

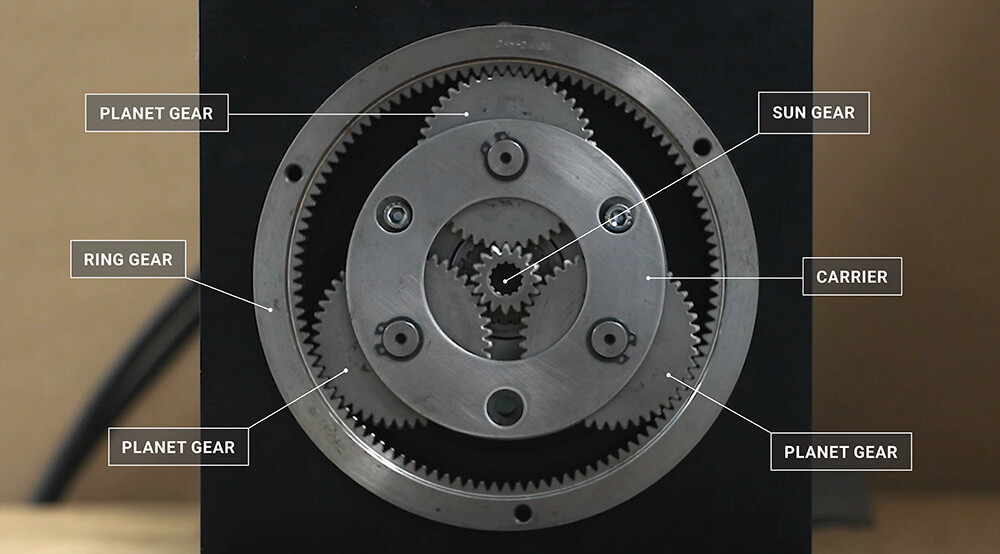

Sun gears are integral components of automatic transmissions in vehicles. Automatic transmissions use planetary gear systems, where the sun gear is one of the key elements. The interaction between the sun gear, planet gears, and ring gear allows for different gear ratios and smooth shifting between gears.

In automatic transmissions, the sun gear is driven by the engine’s input shaft and transmits power to the other gears. By controlling the engagement of various clutches and brakes within the transmission, the sun gear enables seamless gear changes, optimizing vehicle performance and fuel efficiency.

- Transfer Cases:

In four-wheel-drive and all-wheel-drive vehicles, transfer cases distribute power between the front and rear wheels. Sun gears are utilized in transfer cases to facilitate power transfer and gear reduction.

The sun gear, along with other gears and components, helps control the torque distribution and gear ratios between the front and rear axles. This allows vehicles to adapt to different driving conditions, such as slippery surfaces or off-road terrain, enhancing traction and stability.

- Starter Motors:

Sun gears are employed in starter motors, which are responsible for cranking the engine during startup. Starter motors use a gear reduction mechanism to convert the electric motor’s high-speed rotation into a higher torque output.

The sun gear, along with other gears like the planetary gears, enables the gear reduction necessary to generate sufficient torque to crank the engine. This gearing arrangement allows for efficient and reliable engine starting, even in challenging conditions.

- Power Seats and Windows:

Sun gears can also be found in power seat and power window mechanisms in vehicles. These systems use electric motors to adjust seat positions or operate windows.

The sun gear, along with other gears and mechanisms, converts the rotational motion of the electric motor into linear movement, enabling precise adjustments of seat positions or smooth operation of windows. The use of sun gears ensures reliable and efficient functionality of these systems.

- Other Automotive Systems:

Sun gears may also have applications in other automotive systems. For example, they can be found in power steering systems, where they contribute to the gear reduction and power transmission required for smooth steering operation.

Furthermore, sun gears can be utilized in various auxiliary systems, such as cooling fans, HVAC (heating, ventilation, and air conditioning) systems, and engine accessories. These applications leverage the sun gear’s ability to facilitate power transmission and gear reduction, enhancing the efficiency and performance of these systems.

In summary, sun gears are extensively used in automotive applications, including automatic transmissions, transfer cases, starter motors, power seats and windows, power steering systems, and auxiliary systems. Their presence in these systems enables crucial functions such as gear shifting, power distribution, gear reduction, and efficient power transmission. Sun gears contribute to the overall performance, reliability, and functionality of automotive systems, enhancing the driving experience and vehicle efficiency.

How does a sun gear handle variations in load and speed conditions?

A sun gear is designed to handle variations in load and speed conditions in mechanical systems. Its unique positioning and interaction within a planetary gear arrangement contribute to its ability to adapt to changing load and speed requirements. Here’s an explanation of how a sun gear handles variations in load and speed conditions:

- Load Distribution:

In a planetary gear system, the sun gear is located at the center and engages with multiple planet gears, which in turn interact with the outer ring gear. This configuration enables the sun gear to distribute the load among the planet gears. As the load on the system varies, the distribution of load among the planet gears adjusts accordingly. The load distribution mechanism allows the sun gear to handle variations in load conditions by effectively sharing the load across multiple contact points.

- Torque Amplification:

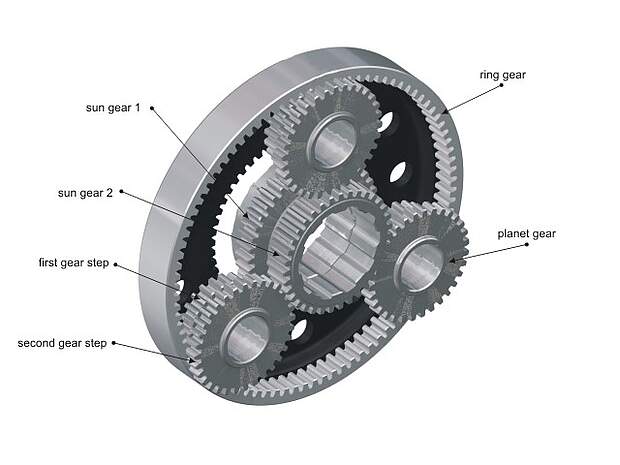

The arrangement of the sun gear, planet gears, and ring gear in a planetary system allows for torque amplification. By changing the number of teeth on the gears and their relative sizes, the gear ratio can be customized. This capability enables the sun gear to adapt to variations in load and speed conditions. When higher torque is required, the gear system can be configured to provide torque amplification by increasing the gear ratio. Conversely, when lower torque is needed, the gear ratio can be adjusted accordingly. This flexibility in gear ratio configuration allows the sun gear to handle variations in load and speed by adapting the torque output.

- Speed Regulation:

Another way the sun gear handles variations in load and speed conditions is through speed regulation. In a planetary gear system, the sun gear’s rotation speed is determined by the input speed and the gear ratio configuration. By adjusting the gear ratio, the rotational speed of the sun gear can be controlled. This speed regulation capability allows the sun gear to adapt to changing speed requirements. When higher speeds are necessary, the gear ratio can be adjusted to increase the rotational speed of the sun gear. Similarly, when lower speeds are desired, the gear ratio can be modified accordingly. The sun gear’s ability to regulate its rotational speed enables it to accommodate variations in load and speed conditions.

- Sturdy Construction:

Sun gears are typically constructed from durable materials such as hardened steel or other high-strength alloys. This robust construction enables them to withstand the forces generated by variations in load and speed conditions. The sturdy design of sun gears ensures that they can handle the stresses and strains associated with changing operating conditions without experiencing premature wear or failure.

In summary, a sun gear handles variations in load and speed conditions through load distribution among the planet gears, torque amplification or reduction based on the gear ratio configuration, speed regulation by adjusting the gear ratio, and its sturdy construction. These features enable the sun gear to adapt to changing requirements, ensuring reliable and efficient operation in various mechanical systems.

What is a sun gear and how does it function in gear systems?

A sun gear is a fundamental component in gear systems, particularly in planetary gear arrangements. It plays a crucial role in determining the overall gear ratio and power distribution within the system. Here’s an explanation of what a sun gear is and how it functions:

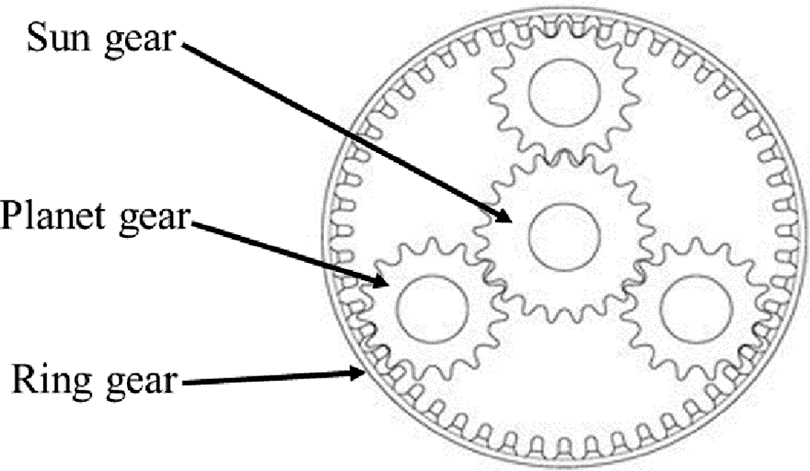

A sun gear is a central gear in a planetary gear set. It is typically located at the center of the gear arrangement and is surrounded by other gears, known as planet gears, as well as an outer ring gear, also called a ring gear or annulus.

The primary function of the sun gear is to transfer torque and provide the driving force in a planetary gear system. Here’s how it functions:

- Power Input: The sun gear receives power input from an external source, such as an engine or motor. It is directly connected to the input shaft and receives rotational motion and torque.

- Planet Gear Engagement: The sun gear engages with multiple planet gears, which are smaller gears that surround the sun gear and mesh with both the sun gear and the ring gear. The planet gears rotate around their own axes while also revolving around the sun gear.

- Power Distribution: As the sun gear rotates, it transmits torque to the planet gears through their meshing teeth. The planet gears, in turn, transfer the torque to the ring gear. The relative sizes of the sun gear, planet gears, and ring gear determine the gear ratio and the distribution of power within the system.

- Gear Ratio Variation: By changing the arrangement and sizes of the sun gear, planet gears, and ring gear, gear systems can achieve different gear ratios. The number of teeth on the sun gear, planet gears, and ring gear, as well as their relative sizes, determine the gear ratio. This allows gear systems to provide various output speeds and torque levels, catering to different operational requirements.

- Directional Control: In some gear systems, the sun gear can also serve as a means of controlling the direction of power transmission. By fixing or holding the sun gear while the ring gear or planet carrier is driven, the gear system can achieve different output directions, such as forward or reverse rotation.

In summary, the sun gear is a central gear in planetary gear systems, responsible for receiving power input, engaging with planet gears, distributing torque to the ring gear, and determining the overall gear ratio. Its function is crucial in achieving different speed and torque combinations, as well as controlling the direction of power transmission within gear systems.

editor by CX 2024-04-09