Product Description

The Advantage of Powder Metallurgy Process

1.Cost effective: The final products can be compacted with powder metallurgy method, and no need or can shorten the processing of machine. It can save material greatly and reduce the production cost.

2.Complex shapes: Powder metallurgy allows to obtaining complex shapes directly from the compacting tooling, without any machining operation, like teeth, splines, profiles, frontal geometries, etc.

3.High precision: Achievable tolerances in the perpendicular direction of compacting are typically IT 8-9 as sintered; improvable up to IT 5-7 after sizing. Additional machining operations can improve the precision.

4.Self-lubrication: The interconnected porosity of the material can be filled with oils, obtaining, and then a self-lubricating bearing; the oil provides constant lubrication between bearing and shaft, and the system does not need any additional external lubricant.

5.Green technology: The manufacturing process of sintered components is certified as ecological, because the material waste is very low, the product is recyclable, and the energy efficiency is good because the material is not molten.

| Product Name | Sun Gear of Sintered Powder Metallurgy Part TW-G17 |

| Material | Powder metal – FD5715 |

| Technology | Powder Metallurgy – Machining |

| Standard | ISO9001 |

| Surface Treatment | High Frequency quenching, Oil impregnation |

| Process Flow | Powder mixing – Forming – Sintering – Oil impregnation – Sizing -Ultrasonic Cleaning – Steam Oxidation – Oil impregnation – Final inspection – Packing |

| Apperance | No Crumbling, Cracks, Exfoliation, Voids, Metal Pitting and Other Defects |

| Application | building industry machinery |

Detail:

Technology :

Workshop:

Packing:

ship:

FAQ:

Q: Do you make customized products based on our design drawings?

A: Yes, we are a professional metal fabrication supplier with experienced engineering team to make custom products according to clients’ drawings.

Q: Will my drawing be safe after you get it?

A: Yes, we won’t release your design to any third parties unless have your permission. And we can CHINAMFG the NDA before you send the drawing.

Q: What is the MOQ?

A: We don’t set MOQ, but the price will be better for the larger quantity . Besides, we are happy to make prototype or sample for clients to ensure quality standard.

Q: Whether some samples can be provided?

A: Yes, just need some sample cost, we will return it back when proceed into mass production.

Q: How to deal with the parts received when they are found to be in poor quality?

A: Please rest assured that all our products are QC inspected and accepted with inspection report before delivery and generally there will no non-conformance: in case of non- conformance, please contact us immediately, take some pictures, we will check on the problems and have them reworked or repaired at the first time , the resulting transportation costs will be our side.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Condition: | New |

|---|---|

| Certification: | CE, ISO9001 |

| Standard: | DIN, ASTM |

| Customized: | Customized |

| Material: | Sintered Metallurgy |

| Application: | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you describe the interaction between sun gears and planet gears?

The interaction between sun gears and planet gears is a fundamental aspect of gear systems. Let’s delve into the details of this interaction:

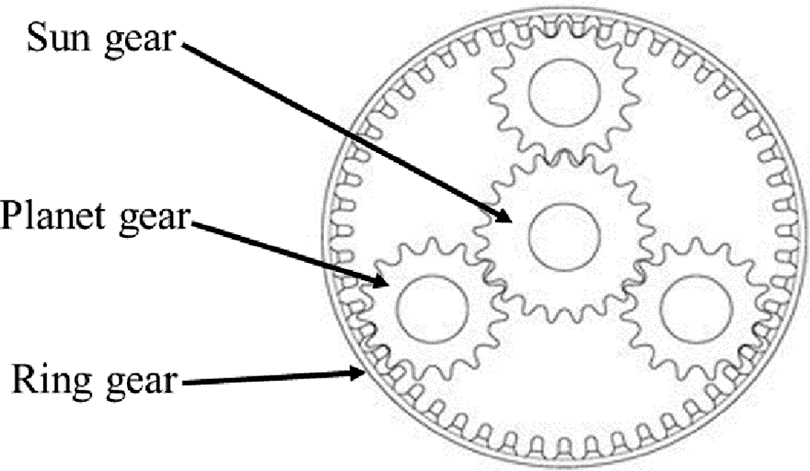

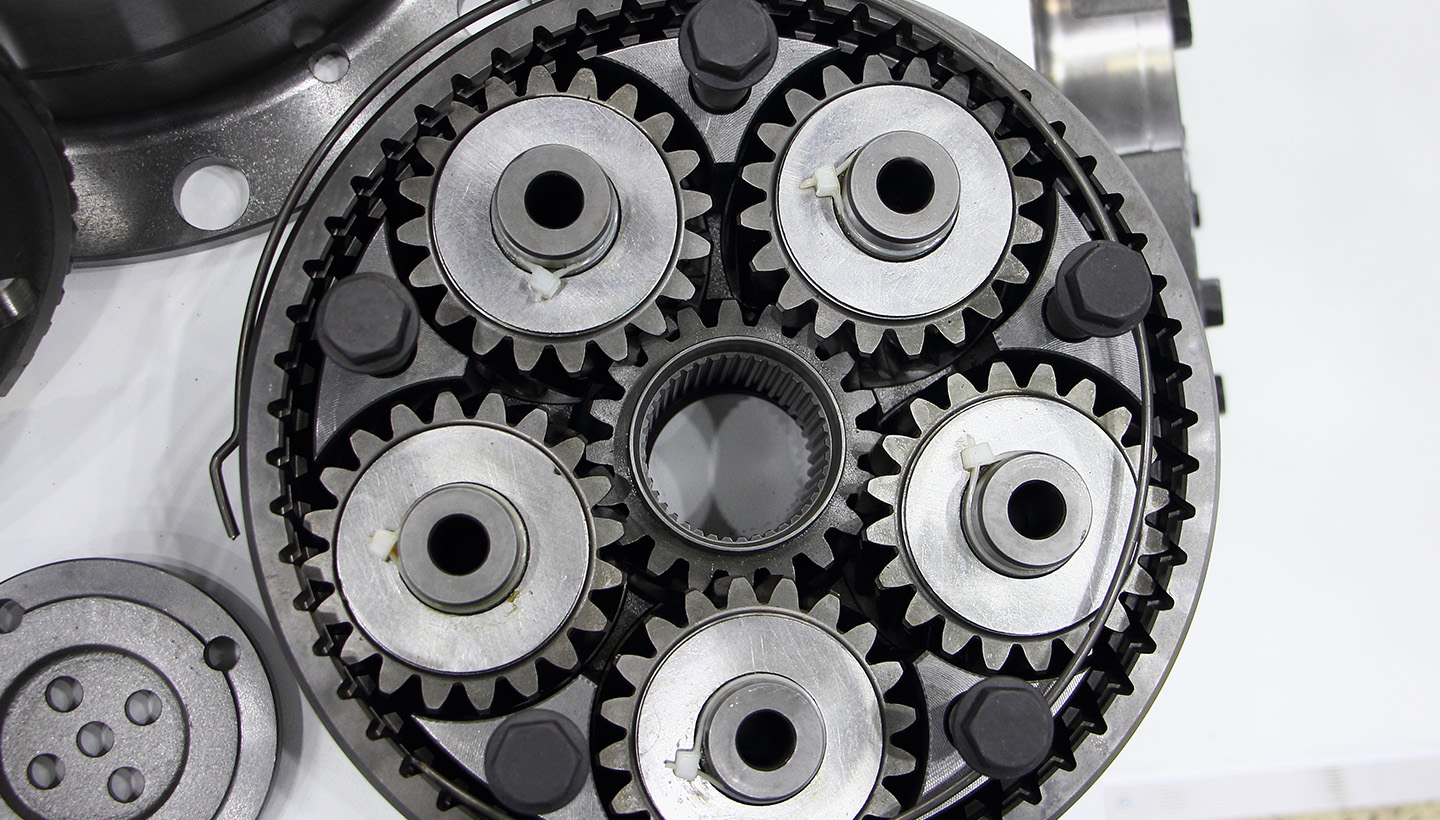

- Planetary Gear Systems:

The interaction between sun gears and planet gears primarily occurs in planetary gear systems. These systems consist of multiple planet gears that rotate around a central sun gear while meshing with an outer ring gear. This arrangement allows for various mechanical advantages and functionalities.

- Power Transmission:

The sun gear serves as the primary driver in a planetary gear system. When power is applied to the sun gear, it transmits rotational force to the planet gears. The planet gears, due to their meshing with both the sun gear and the ring gear, distribute the transmitted power evenly across all the gears.

As the sun gear rotates, the planet gears rotate in the opposite direction around the sun gear while also rotating around their own axes. This rotational movement of the planet gears, driven by the sun gear, plays a crucial role in power transmission within the gear system.

- Speed and Torque Ratios:

The interaction between the sun gear and planet gears affects the speed and torque ratios in a gear system. By choosing different sizes for the sun gear and planet gears, engineers can manipulate the gear ratios to achieve specific outcomes.

When the sun gear is larger than the planet gears, it results in a higher speed ratio. In this case, the sun gear rotates faster than the planet gears, leading to an output shaft or ring gear with increased rotational speed relative to the input shaft or sun gear.

Conversely, when the sun gear is smaller than the planet gears, it leads to a lower speed ratio. In this scenario, the sun gear rotates slower than the planet gears, resulting in an output shaft or ring gear with reduced rotational speed compared to the input shaft or sun gear.

Similarly, the interaction between the sun gear and planet gears affects the torque ratio. When the sun gear is larger than the planet gears, it amplifies the torque, resulting in higher output torque relative to the input torque. Conversely, when the sun gear is smaller, it reduces the torque, resulting in lower output torque compared to the input torque.

- Direction Reversal:

The interaction between the sun gear and planet gears also enables torque direction reversal in planetary gear systems. When the sun gear rotates in a specific direction, it imparts torque to the planet gears, causing them to rotate in the opposite direction around the sun gear.

This counterclockwise rotation of the planet gears, as driven by the sun gear, leads to the ring gear rotating in the opposite direction. By reversing the direction of the sun gear’s rotation, the torque direction can be reversed once again. This ability to change torque direction makes planetary gear systems versatile and applicable in various mechanical and automotive applications.

- Mechanical Advantages:

The interaction between sun gears and planet gears offers several mechanical advantages. The distribution of torque across multiple planet gears allows for increased load-bearing capacity and improved system reliability. As each planet gear shares the load, the overall stress on individual gears is reduced, enhancing the system’s durability.

Moreover, the arrangement of sun gears and planet gears in a planetary gear system results in compact designs and high power density. The distributed power transmission and torque-sharing characteristics enable the system to handle higher loads while occupying minimal space.

In summary, the interaction between sun gears and planet gears in planetary gear systems is crucial for power transmission, achieving speed and torque ratios, enabling torque direction reversal, and providing mechanical advantages such as load distribution and compact designs. Understanding this interaction is essential for designing and optimizing gear systems in various applications.

How does a sun gear handle variations in load and speed conditions?

A sun gear is designed to handle variations in load and speed conditions in mechanical systems. Its unique positioning and interaction within a planetary gear arrangement contribute to its ability to adapt to changing load and speed requirements. Here’s an explanation of how a sun gear handles variations in load and speed conditions:

- Load Distribution:

In a planetary gear system, the sun gear is located at the center and engages with multiple planet gears, which in turn interact with the outer ring gear. This configuration enables the sun gear to distribute the load among the planet gears. As the load on the system varies, the distribution of load among the planet gears adjusts accordingly. The load distribution mechanism allows the sun gear to handle variations in load conditions by effectively sharing the load across multiple contact points.

- Torque Amplification:

The arrangement of the sun gear, planet gears, and ring gear in a planetary system allows for torque amplification. By changing the number of teeth on the gears and their relative sizes, the gear ratio can be customized. This capability enables the sun gear to adapt to variations in load and speed conditions. When higher torque is required, the gear system can be configured to provide torque amplification by increasing the gear ratio. Conversely, when lower torque is needed, the gear ratio can be adjusted accordingly. This flexibility in gear ratio configuration allows the sun gear to handle variations in load and speed by adapting the torque output.

- Speed Regulation:

Another way the sun gear handles variations in load and speed conditions is through speed regulation. In a planetary gear system, the sun gear’s rotation speed is determined by the input speed and the gear ratio configuration. By adjusting the gear ratio, the rotational speed of the sun gear can be controlled. This speed regulation capability allows the sun gear to adapt to changing speed requirements. When higher speeds are necessary, the gear ratio can be adjusted to increase the rotational speed of the sun gear. Similarly, when lower speeds are desired, the gear ratio can be modified accordingly. The sun gear’s ability to regulate its rotational speed enables it to accommodate variations in load and speed conditions.

- Sturdy Construction:

Sun gears are typically constructed from durable materials such as hardened steel or other high-strength alloys. This robust construction enables them to withstand the forces generated by variations in load and speed conditions. The sturdy design of sun gears ensures that they can handle the stresses and strains associated with changing operating conditions without experiencing premature wear or failure.

In summary, a sun gear handles variations in load and speed conditions through load distribution among the planet gears, torque amplification or reduction based on the gear ratio configuration, speed regulation by adjusting the gear ratio, and its sturdy construction. These features enable the sun gear to adapt to changing requirements, ensuring reliable and efficient operation in various mechanical systems.

What is the significance of the positioning of the sun gear in planetary gear arrangements?

The positioning of the sun gear in planetary gear arrangements holds significant importance and directly impacts the functionality and performance of the gear system. Understanding the significance of sun gear positioning helps in comprehending how different configurations can be utilized to achieve specific objectives. Here’s an explanation of the significance of the positioning of the sun gear in planetary gear arrangements:

- Power Input: The sun gear serves as the primary power input element in a planetary gear arrangement. Its central position allows it to receive rotational motion and torque from an external source, such as an engine or motor. Being the input gear, the sun gear plays a crucial role in transmitting power to other gears within the system.

- Interaction with Planet Gears: The positioning of the sun gear at the center of a planetary gear arrangement enables its engagement with multiple planet gears. The planet gears, which are smaller gears surrounding the sun gear, mesh with both the sun gear and an outer ring gear. This interaction between the sun gear and planet gears facilitates the transfer of torque and motion between the gears.

- Torque Distribution: As the sun gear rotates, it transmits torque to the planet gears through their meshing teeth. The planet gears, in turn, transfer the torque to the outer ring gear. The positioning of the sun gear, along with the arrangement of the planet gears and ring gear, allows for torque distribution among the gears. This torque distribution mechanism enables efficient load sharing and prevents excessive stress on any single gear, enhancing the overall durability and performance of the gear system.

- Gear Ratio Control: The positioning of the sun gear in relation to the planet gears and the ring gear determines the gear ratio of the planetary gear arrangement. By changing the arrangement and sizes of these gears, different gear ratios can be achieved. The number of teeth on the sun gear, planet gears, and ring gear, as well as their relative sizes, play a crucial role in determining the gear ratio. This flexibility in gear ratio control allows for the customization of output speeds and torque levels to suit specific application requirements.

- Torque Amplification: The positioning of the sun gear in a planetary gear arrangement enables torque amplification. By utilizing the interaction between the sun gear, planet gears, and ring gear, the gear system can multiply or reduce torque based on the gear ratio configuration. This torque amplification feature is particularly advantageous in applications where high torque output is needed, such as automotive transmissions and heavy machinery.

- Directional Control: The positioning of the sun gear also contributes to the directional control capability of a planetary gear arrangement. By fixing or holding the sun gear while the ring gear or planet carrier is driven, the gear system can achieve different output directions, such as forward or reverse rotation. This directional control adds versatility to the gear system, allowing it to be used in various mechanical applications.

In summary, the positioning of the sun gear in planetary gear arrangements is significant for power input, interaction with planet gears, torque distribution, gear ratio control, torque amplification, and directional control. The central position of the sun gear enables efficient power transmission, load sharing, and customization of gear ratios, making planetary gear arrangements with a sun gear suitable for a wide range of mechanical applications.

editor by CX 2024-04-17