Product Description

Machining Capability

Our Gear, Pinion Shaft, Ring Gear Capabilities:

| Capabilities of Gears/ Splines | ||||||

| Item | Internal Gears and Internal Splines | External Gears and External Splines | ||||

| Milled | Shaped | Ground | Hobbed | Milled | Ground | |

| Max O.D. | 2500 mm | |||||

| Min I.D.(mm) | 30 | 320 | 20 | |||

| Max Face Width(mm) | 500 | 1480 | ||||

| Max DP | 1 | 0.5 | 1 | 0.5 | ||

| Max Module(mm) | 26 | 45 | 26 | 45 | ||

| DIN Class Level | DIN Class 8 | DIN Class 4 | DIN Class 8 | DIN Class 4 | ||

| Tooth Finish | Ra 3.2 | Ra 0.6 | Ra 3.2 | Ra 0.6 | ||

| Max Helix Angle | ±22.5° | ±45° | ||||

Our Main Products

1. Spur Gear

2. Planetary Gear

3. Metal Gears

4. CHINAMFG

5. Ring Gear

6. Gear Shaft

7. Helical Gear

8. Pinion Gear

9. Spline Shaft

Company Profile

1. 21 years experience in high quality gear, gear shaft’s production, sales and R&D.

2. Our Gear, Gear Shaft are certificated by ISO9001: 2008 and ISO14001: 2004.

3. CHINAMFG has more than 50 patents in high quality Gear, Gear Shaft manufacturing.

4. CHINAMFG products are exported to America, Europe.

5. Experience in cooperate with many Fortune 500 Companies

Our Advantages

1) In-house capability: OEM service as per customers’ requests, with in-house tooling design & fabricating

2) Professional engineering capability: On product design, optimization and performance analysis

3) Manufacturing capability range: DIN 3960 class 8 to 4, ISO 1328 class 8 to 4, AGMA 2000 class 10-15, JIS 1702-1703 class 0 to 2, etc.

4) Packing: Tailor-made packaging method according to customer’s requirement

5) Just-in-time delivery capability

FAQ

1. Q: Can you make as per custom drawing?

A: Yes, we can do that.

2. Q: If I don’t have drawing, what can you do for me?

A: If you don’t have drawing, but have the sample part, you may send us. We will check if we can make it or not.

3. Q: How do you make sure the quality of your products?

A: We will do a series of inspections, such as:

A. Raw material inspection (includes chemical and physical mechanical characters inspection),

B. Machining process dimensional inspection (includes: 1st pc inspection, self inspection, final inspection),

C. Heat treatment result inspection,

D. Gear tooth inspection (to know the achieved gear quality level),

E. Magnetic particle inspection (to know if there’s any cracks in the gear).

We will provide you the reports 1 set for each batch/ shipment.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Wind Turbine |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the safety considerations when working with sun gears in machinery?

Working with sun gears in machinery requires careful attention to safety to prevent accidents and ensure the well-being of operators. Here are some important safety considerations when working with sun gears:

- Training and Knowledge:

Operators and maintenance personnel should receive proper training and have a thorough understanding of the machinery’s operation and the specific risks associated with working with sun gears. This includes knowledge of safety procedures, maintenance protocols, and the use of personal protective equipment (PPE).

- Lockout/Tagout Procedures:

Before performing any maintenance or repair tasks on machinery involving sun gears, it is essential to follow lockout/tagout procedures. These procedures involve isolating the machinery from its power source and ensuring that it cannot be accidentally energized during maintenance. Lockout/tagout procedures help prevent unexpected movements of the gears, reducing the risk of injury.

- Personal Protective Equipment (PPE):

Appropriate personal protective equipment should be worn when working with sun gears. This may include safety glasses, gloves, protective clothing, and hearing protection, depending on the specific hazards present. PPE helps protect operators from potential injuries caused by flying debris, contact with moving parts, and excessive noise.

- Machine Guards:

Machine guards should be in place to prevent accidental contact with the sun gears during operation. Guards can be physical barriers, such as covers or enclosures, that restrict access to the gears. They act as a protective barrier and reduce the risk of entanglement or injury caused by accidental contact with rotating or moving parts.

- Maintenance and Inspection:

Regular maintenance and inspection of machinery, including sun gears, are crucial for identifying potential issues and preventing malfunctions or failures. Maintenance tasks should be carried out following manufacturer guidelines and recommendations. Inspection of gears should include checking for signs of wear, proper lubrication, and alignment.

- Proper Handling and Lifting:

When handling sun gears or transporting them within a facility, proper lifting techniques and equipment should be used. Sun gears can be heavy and require appropriate lifting devices, such as cranes or hoists, to avoid strain or injuries. Operators should also ensure that gears are securely fastened or stored to prevent them from falling or causing accidents.

- Risk Assessment:

A comprehensive risk assessment should be conducted to identify hazards associated with sun gears and their machinery. The assessment should consider factors such as gear size, rotational speed, pinch points, and potential for entanglement. Based on the assessment, appropriate safety measures and controls should be implemented to mitigate identified risks.

- Emergency Procedures:

Clear emergency procedures should be established and communicated to all personnel working with sun gears. These procedures should include protocols for responding to accidents, injuries, or equipment malfunctions. Operators should be familiar with emergency shutdown procedures and know how to safely stop the machinery in case of an emergency.

By adhering to these safety considerations, operators and maintenance personnel can minimize the risk of accidents and promote a safe working environment when working with sun gears in machinery.

How does a sun gear handle variations in load and speed conditions?

A sun gear is designed to handle variations in load and speed conditions in mechanical systems. Its unique positioning and interaction within a planetary gear arrangement contribute to its ability to adapt to changing load and speed requirements. Here’s an explanation of how a sun gear handles variations in load and speed conditions:

- Load Distribution:

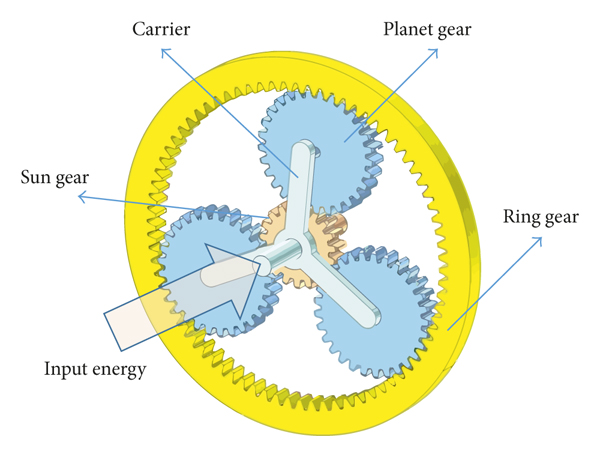

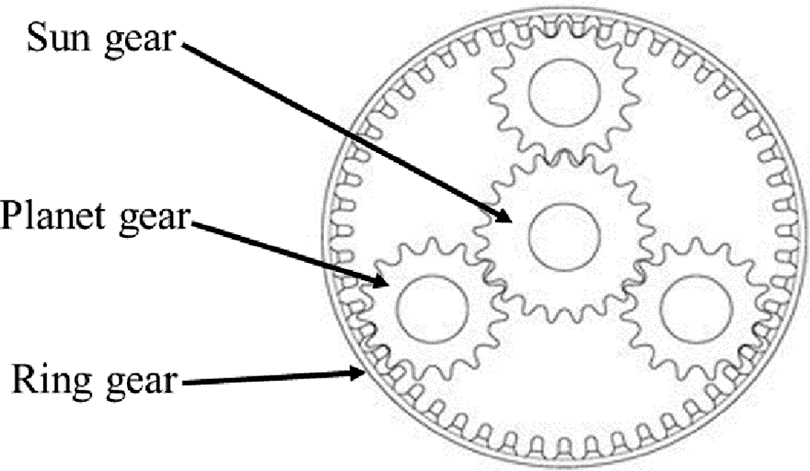

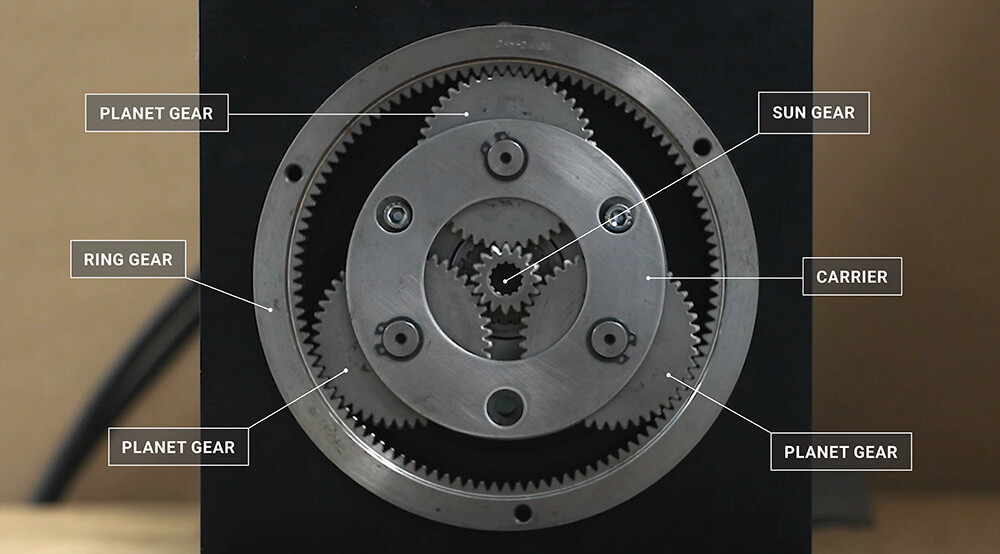

In a planetary gear system, the sun gear is located at the center and engages with multiple planet gears, which in turn interact with the outer ring gear. This configuration enables the sun gear to distribute the load among the planet gears. As the load on the system varies, the distribution of load among the planet gears adjusts accordingly. The load distribution mechanism allows the sun gear to handle variations in load conditions by effectively sharing the load across multiple contact points.

- Torque Amplification:

The arrangement of the sun gear, planet gears, and ring gear in a planetary system allows for torque amplification. By changing the number of teeth on the gears and their relative sizes, the gear ratio can be customized. This capability enables the sun gear to adapt to variations in load and speed conditions. When higher torque is required, the gear system can be configured to provide torque amplification by increasing the gear ratio. Conversely, when lower torque is needed, the gear ratio can be adjusted accordingly. This flexibility in gear ratio configuration allows the sun gear to handle variations in load and speed by adapting the torque output.

- Speed Regulation:

Another way the sun gear handles variations in load and speed conditions is through speed regulation. In a planetary gear system, the sun gear’s rotation speed is determined by the input speed and the gear ratio configuration. By adjusting the gear ratio, the rotational speed of the sun gear can be controlled. This speed regulation capability allows the sun gear to adapt to changing speed requirements. When higher speeds are necessary, the gear ratio can be adjusted to increase the rotational speed of the sun gear. Similarly, when lower speeds are desired, the gear ratio can be modified accordingly. The sun gear’s ability to regulate its rotational speed enables it to accommodate variations in load and speed conditions.

- Sturdy Construction:

Sun gears are typically constructed from durable materials such as hardened steel or other high-strength alloys. This robust construction enables them to withstand the forces generated by variations in load and speed conditions. The sturdy design of sun gears ensures that they can handle the stresses and strains associated with changing operating conditions without experiencing premature wear or failure.

In summary, a sun gear handles variations in load and speed conditions through load distribution among the planet gears, torque amplification or reduction based on the gear ratio configuration, speed regulation by adjusting the gear ratio, and its sturdy construction. These features enable the sun gear to adapt to changing requirements, ensuring reliable and efficient operation in various mechanical systems.

Can you explain the role of a sun gear in planetary gear systems?

The sun gear plays a crucial role in planetary gear systems, contributing to their unique functionality and versatility. Understanding the specific role of the sun gear within these systems helps in comprehending their overall operation. Here’s an explanation of the role of a sun gear in planetary gear systems:

- Power Input: The sun gear serves as the primary power input element in a planetary gear system. It receives rotational motion and torque from an external source, such as an engine or motor. This power input is transmitted to other gears within the system.

- Engagement with Planet Gears: One of the distinctive features of a planetary gear system is the interaction between the sun gear and multiple planet gears. The planet gears are smaller gears that surround the sun gear and mesh with both the sun gear and an outer ring gear. This engagement allows for the transfer of torque and motion between the gears.

- Power Distribution: As the sun gear rotates, it transmits torque to the planet gears through their meshing teeth. The planet gears, in turn, transfer the torque to the outer ring gear. This power distribution mechanism enables the sharing of torque among multiple gears within the system, allowing for load distribution and efficient power transmission.

- Gear Ratio Control: By changing the arrangement and sizes of the sun gear, planet gears, and ring gear, planetary gear systems can achieve different gear ratios. The number of teeth on the sun gear, planet gears, and ring gear, as well as their relative sizes, determine the gear ratio. This flexibility in gear ratio control enables planetary gear systems to provide various output speeds and torque levels, catering to different operational requirements.

- Torque Amplification: A key advantage of planetary gear systems is their ability to amplify torque. By employing a combination of the sun gear, planet gears, and ring gear, torque can be multiplied or reduced depending on the gear ratio configuration. This torque amplification feature is beneficial in applications where high torque output is required, such as automotive transmissions and heavy machinery.

- Directional Control: Another notable aspect of planetary gear systems is their directional control capability. By fixing or holding the sun gear while the ring gear or planet carrier is driven, the gear system can achieve different output directions, such as forward or reverse rotation. This directional control adds versatility to gear systems, enabling them to be used in various mechanical applications.

In summary, the sun gear in planetary gear systems serves as the power input element, engages with planet gears, distributes torque, controls gear ratios, provides torque amplification, and enables directional control. Its role is essential in achieving efficient power transmission, versatile gear ratios, and adaptable functionality in a wide range of mechanical applications.

editor by CX 2024-04-09